Hash Heat Lessons Learned

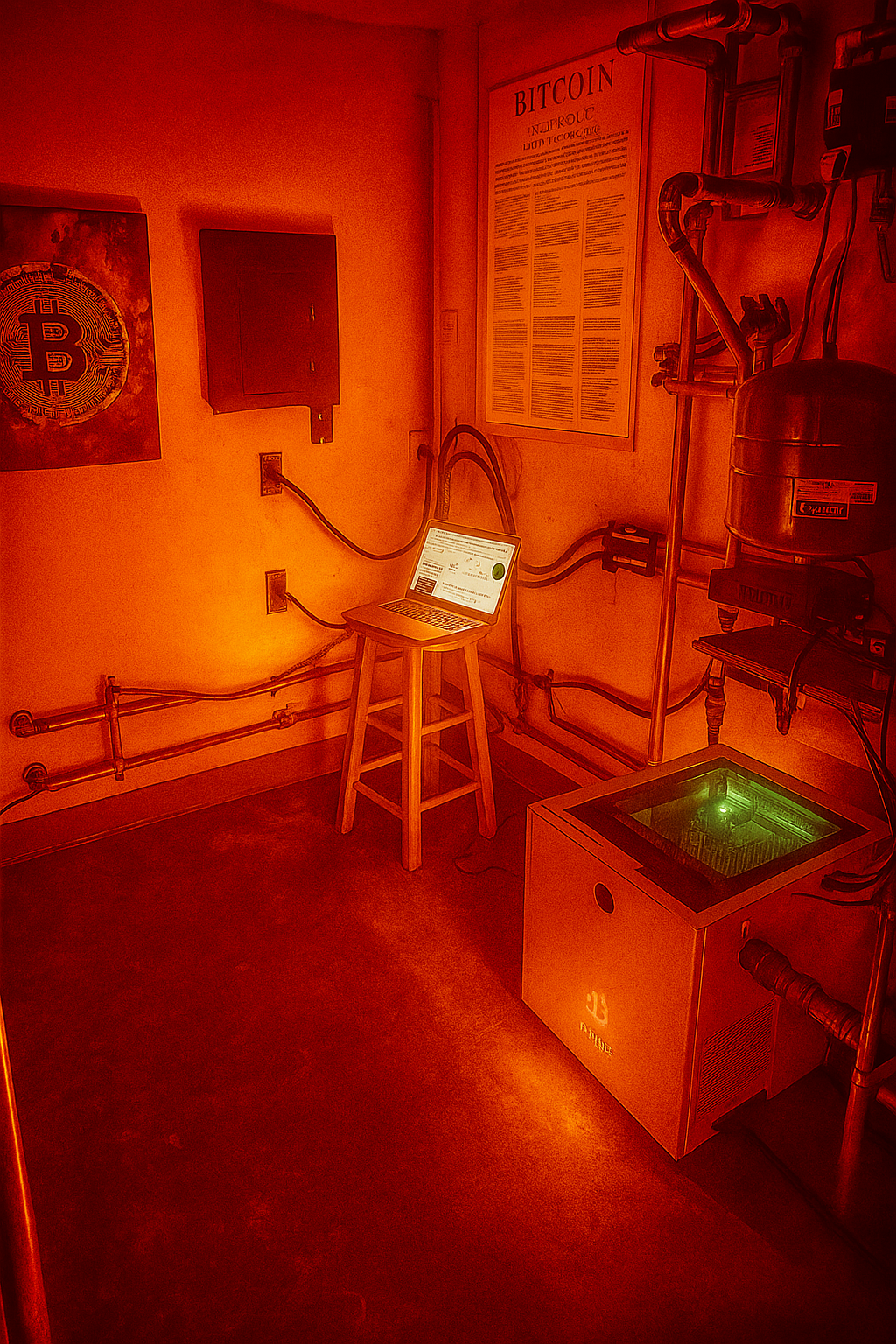

Heating a shop with Bitcoin miners sounds simple in theory—capture the waste heat, put it to work, and get “free” heat out of the mining process. But actually engineering a reliable hydronic system around immersion-cooled miners taught me far more than I expected. These are the real-world lessons from the shop-heating project that forced multiple redesigns, wasted gallons of fluid, and ultimately helped me understand how to engineer a stable, resilient heat-recovery system.

The Original Plan: Use a 3-Way Valve to Split Heat Between the Slab and the Dry Cooler

My first design looked good on paper:

Run the miners in immersion oil.

Pump the hot oil through a plate-and-frame heat exchanger to transfer heat to the glycol loop.

Circulate that hot glycol through PEX embedded in the concrete slab.

Use a dry cooler to dump excess heat.

Control everything with a simple thermostat and a 3-way valve:

If the shop needed heat: glycol stayed in the slab loop.

If the shop hit the set point: the valve sent glycol to the dry cooler.

It all worked… until it didn’t.

The Big Failure: A Binary Valve in a System That Needed Modulation

The flaw wasn’t the valve—it was the binary nature of the valve.

When the thermostat told the system “the shop is warm enough,” the 3-way valve instantly snapped to the dry cooler position.

This created a major problem:

Sudden, full-flow cooling caused the miner oil temperature to crash.

Immersion miners hate rapid temperature swings:

It stresses the hashboards.

It can cause instability.

It forces the system to chase temps instead of maintaining them.

What I really needed wasn’t an ON/OFF valve—it was a dynamic mixing valve that could modulate how much heat went to the dry cooler without shocking the system.

Lesson learned: abrupt changes break thermal systems. Smooth transitions keep miners alive.

Redesigning the System: Sending Immersion Oil Through the Dry Cooler

To fix the temperature swing issue, I changed the whole approach:

Instead of routing

glycol

to the dry cooler,

I routed the immersion oil itself through the dry cooler, in line with the heat exchanger.

This accomplished three things:

The dry cooler became a consistent final cooling stage.

The miners received stable injection oil temperatures.

The system no longer relied on abrupt valve movements.

But making this change came with its own challenges.

The Dry Cooler Flush That Wasted Too Much Immersion Oil

Dry coolers don’t fully drain. Anyone who has ever tried knows that:

Glycol hides in low spots.

Water traps itself in tubes.

Air pockets make flushing inconsistent.

The only way to truly clean it was to flush immersion oil through it, which cost me more BitCool than I’d like to admit.

Lesson learned: never mix water/glycol hardware with oil unless you have a dedicated purge plan.

New Issue: The Heat Exchanger Was Undersized

Once the dry cooler was re-plumbed, I expected improved performance. Instead I found another bottleneck:

My heat exchanger simply couldn’t transfer enough heat into the glycol loop.

Symptoms:

The radiant slab wasn’t capturing enough heat.

Too much heat bypassed the exchanger.

The dry cooler dumped more heat than I wanted.

The miners were producing plenty of thermal energy—it just wasn’t getting into the concrete where it belonged.

A larger or dual heat exchanger would:

Absorb far more heat into the slab

Reduce waste heat dumping

Improve miner temperature stability

Lower overall operating costs

Lesson learned: your heat exchanger is the “throat” of the system—if it’s undersized, your whole design suffers.

Improved Control Sequence: The Thermostat Now Runs the Glycol Pump

One of the biggest improvements came from a simple control change:

The thermostat now controls the glycol pump directly.

When the shop is cold → the thermostat starts the glycol pump.

When the shop reaches temperature → the thermostat shuts the pump off.

This ensures:

The floor only pulls heat when it’s needed.

The slab doesn’t become a runaway heat sink.

Miners aren’t forced into huge thermal swings.

The hydronic loop acts as a demand-based heat absorber.

This pump-controlled strategy works far better than relying on a 3-way valve because it introduces gentle, predictable load changes that immersion systems can tolerate.

Lesson learned: in hydronics, sequencing is as important as plumbing.

Time, Energy, Money… and Why It Was Still Worth It

Every redesign cost something:

Time draining, flushing, rewiring, and replumbing

Energy wrestling with pumps, fittings, and troubleshooting

Money replacing fluids, valves, and components

But every dollar and hour taught me something I couldn’t have learned any other way.

Key takeaways from the entire project:

Immersion miners crave stable, predictable temperatures.

Avoid binary control in thermal systems—modulate whenever possible.

Dry coolers trap fluid; plan for proper purge systems.

Heat exchangers determine how much heat you can actually recover.

Pump-based control sequencing stabilizes the system far better than simple valves.

Once dialed in, heating with Bitcoin mining is powerful, efficient, and incredibly satisfying.

I’m heating a shop with Bitcoin miners—and I learned every lesson the hard way. But now that the system is dialed in, the blueprint for future installations is stronger than ever.